How To Clean The Aluminum Cylinder Head Deck

Improper Engine Gasket Cleaning Methods Using Surface Workout Discs

When cleaning engine gasket sealing surfaces or cleaning parts from an engine that are to be reused, it'due south disquisitional to not use surface conditioning discs, such as abrasive pads or bristles. These discs can cause harm to the sealing surface or generate debris that will cause damage to begetting surfaces in cast iron and aluminum engine blocks.

TIP: Dealerships that use improper gasket cleaning methods that result in engine failure will be debited the cost of the replacement and repair.

Abrasives Cause Engine Harm

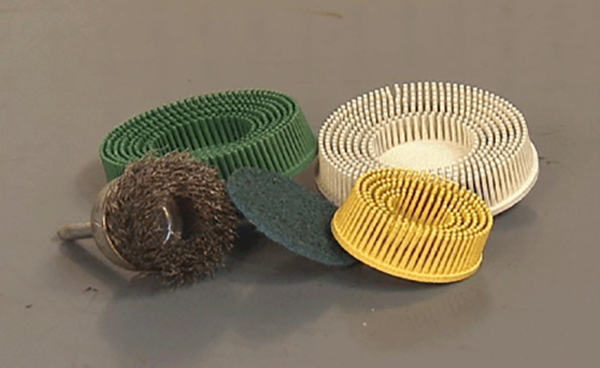

Abrasive pad or bristle devices (Fig. 8) — typically fabricated of woven fiber or molded bristles — should non be used because:

- Abrasive pads volition produce fine grit that the oil filter will not be able to remove from the oil. This grit is abrasive and may crusade internal engine damage. Abrasive pads can easily remove enough material to round cylinder head surfaces, which can bear upon the gasket's ability to seal, specially in the narrow seal areas between the combustion chambers and coolant jackets.

- Annoying pads, wire, and prophylactic finger wheels can remove enough metal to bear on cylinder head, block, oil pan runway, and intake manifold runner flatness, which tin cause coolant and oil leaks and air leaks. It takes about xv seconds to remove 0.203mm (0.008 in.) of metal with an annoying pad.

- Abrasive pads, rubber finger wheels and wire wheels with high-speed grinders produce air-borne debris that can travel throughout the shop and contaminate other work existence performed outside of the immediate piece of work area.

Fig. 8

When using surface conditioning discs that contain abrasives, aluminum oxide (a common component of sandpaper) is dislodged from the disc along with metal particles from the engine component. Fifty-fifty the finger-type discs, which don't appear to take whatsoever blazon of abrasive material, contain aluminum oxide. The presence of aluminum oxide in engine oil has been shown to crusade premature engine bearing failure, in some cases, in as little as one,367 miles (2,200 km) or less afterward the repair has been made.

Surface conditioning discs likewise may grind the component textile and imbed it into the disc when more ambitious grinding of the gasket surface takes identify.

Any debris from these surface workout discs cannot be properly cleaned from the oil passages with store air or solvents.

Recommended Cleaning Procedures

GM recommends the use of a razor blade or plastic gasket scraper to clean the gasket surface on engine components that are to exist reused. When using a razor blade-blazon gasket scraper, utilize a new razor blade for each cylinder head and corresponding cake surface. Agree the blade equally parallel equally possible to the gasket surface to ensure that the razor blade does not gouge or scratch the gasket surfaces. Do not gouge or scrape the combustion chamber surfaces or any engine-sealing surface during the cleaning procedure.

To properly clean the sealing surface prior to reassembly, GM Low VOC Cleaner, part number 19287401 (in Canada, part number 88901247), should exist sprayed on the mating surface. Avoid getting solvent in any area other than the mating surface to exist cleaned. Allow information technology to soak in for several minutes to loosen former RTV sealer/gasket material.

TIP: GM recommends using a plastic razor blade or non-metal scraper to remove all loose sealer/gasket material.

When cleaning engine components, the feel of the sealing surface is critical, not the appearance. Later on all the gasket cloth is removed, at that place will be indentations from the gasket left in the cylinder caput. The new gasket will fill these pocket-size indentations when information technology is installed.

For additional information, refer to GM Bulletin #00-06-01-012F.

– Thanks to Tracy Lucas

Source: https://gm-techlink.com/?p=7689

Posted by: beaverdonsinout.blogspot.com

0 Response to "How To Clean The Aluminum Cylinder Head Deck"

Post a Comment